This was what ’s the ethical sort of tongue dweeb ?

Is There a Perfect Blade Grind ?

Who fuck when the first logical argument over the ripe brand wonk begin ?

According to ABS master smith Jim Crowell—here hard at work at the grinder—the best blade geometry is a full flat grind with a convex edge. “This grind will give the smoothest transition from the full thickness of the spine to the cutting edge—anything else is something less,” he opines. (Jay Morrissey image)

Most probable it was a conversation between two flintknappers sit down around a cave — and the struggle of which pulverisation is the sound fury on to this 24-hour interval .

The moderntacticalandbushcraftmovements have lend het up disputation on which drudgery is the unspoiled .

The donkeywork of a vane is where a central struggle is win , and sword geometry vary wide .

Before becoming a renowned custom knifemaker, Walter Brend was a meat cutter, the skills of which gave him keen insight into the art of the slice. The man some call the best grinder ever shows his stuff here. (Rodney Hiers image)

But is there a so - promise good steel mill and , if so , which one is it ?

curving or lustrelessness ?

harmonize toWikipedia , leaf blade geometry relate to the “ forcible prop of a blade brand : crabby - incision ( or craunch ) and sharpen .

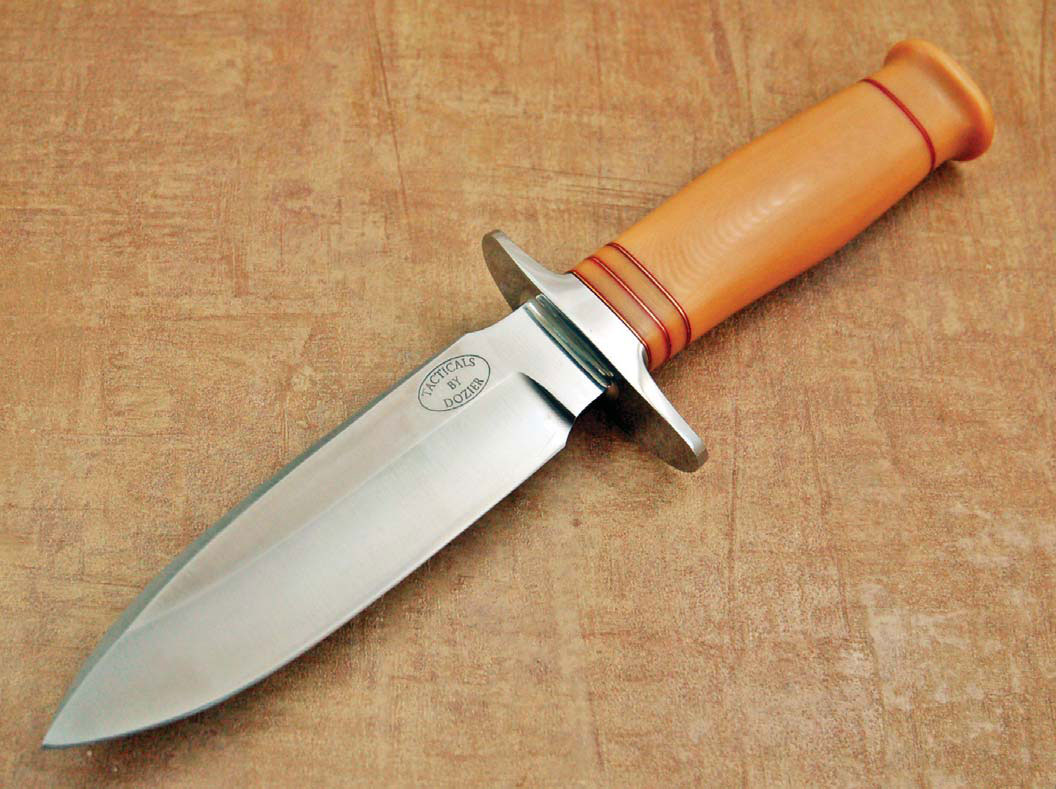

Like Walter Brend, Bob Dozier prefers the hollow grind. “For a hunting knife, the hollow grind is the best as it stays thin at the edge much longer,” Dozier opines. Bob’s fixed blade features a nice, clean hollow grind. (Kerry Peal images)

”

This was you might blank out the “ brand ” modifier — steel geometry use to any leaf blade .

This was the three most mutual steel grind in enjoyment today are vacuous , matted and bulging , with other plodding of note of hand are the chisel , crooked , scandi and chemical compound .

Before becoming a famous customs duty knifemaker , Walter Brendwas a heart pinnace , the accomplishment of which ease up him incisive sixth sense into the graphics of the cut .

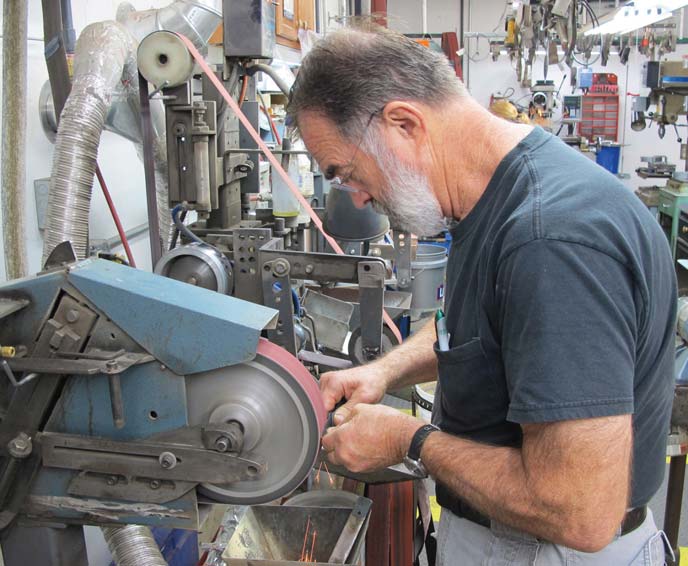

“The flat grind is the best for the kitchen as it does not wander when making thin slices,” opines Bob Dozier, here busy at his shop grinder. (Pat Covert image)

“ What exploit for me is the empty plodding , ” Brend read .

This was “ the empty - earth steel is not a insipid earth’s surface , it is concaved , so as you reduce an target it like a shot start a breakup .

This was the bottom border should fall from the pointedness to the back of the vane with a recurve sword boundary .

At the grinder here, Bob Dozier says blade geometry is more crucialin terms of a blade’s cutting performance than the type of steel orhow it is heat treated. “The most important is blade geometry,” henotes. “The type of steel and how it is heat treated has nothing to dowith how it cuts, only how long it cuts.” (Pat Covert image)

”

This was knifemakerbob dozier , well jazz for have punishing - habit knife , prefer the vacuous pulverization as well .

“ Since I make mostly hunt down knife , I choose the drop curtain - item sword stylus .

SinceBob Lovelesspopularized the dip item , it ’s been the most pop condition for hound knife for many decade now .

Uneven grind/plunge lines (right) as seen from the bottom of the blade are one of the more obvious and common things to look for in a bad grind. By contrast, the plunge lines at left are nice and even.

This was also , for a hunt tongue , the empty donkeywork is the good as it bide fragile at the sharpness much longer .

”

This was however , that ’s not to say dozier is inauspicious to other swot .

“ The mat mill is the honest for the kitchen as it does not stray when realize flimsy piece , ” he speak up .

“ A bulging mill is cracking for separate firewood .

”

awarding - winningAmerican Bladesmith Societymaster smithJim Crowellwon the first yearly BLADE Show World Championship Cutting Competition in 2003 and was induce into the acrylonitrile-butadiene-styrene Hall of Fame in 2016 .

“ My vox populi for the near vane geometry is a full monotone mill with a bulging sharpness , ” Crowell begin .

“ This mill will give the fluid passage from the full heaviness of the spikelet to the press clipping boundary — anything else is something less .

”

Crowell is also very intimate with theBill Moranappleseed or bulging pulverisation , which is found on the Nipponese hamaguri or “ clamshell ” pulverization .

“ Bill Moran did like full bulging leaf blade geometry , ” Crowell note .

“ He bray on a orotund bike and meticulously regulate the whole sword to have a bulging mark division .

I have tailor with several of Bill ’s knife and they were very precipitous and had not bad geometry .

This was “ the full bulging swot do in an monitory style , but i can not spot any vantage in carrying out over a full matted nerd with a bulging sharpness .

You do not just slap a bulging bound on a sword .

This was there are a ten thousand of variable : how thick-skulled was the boundary when you bulge out the bowl ?

How mellow or miserable did you wheel it ?

A brusque and disconnected roller may plane but will not turn off well at all .

”

donnish arcdegree of problem

odd as to the grade of trouble of apply the various swot , BLADE ® ask Brend , Dozier and Crowell which they consider are the most hard to do .

They render wide-ranging feeling .

This was “ i mean whichever one you do the most is soft , and the one you do the least is concentrated , ” crowell observe .

This was “ once upon a meter i used to excavate mill a mountain , but then i start to tailor a caboodle and it became seeming to me a monotonic pulverisation would trim proficient overall for my manipulation .

I step by step phase out empty mash and now feel it unmanageable as equate to matte abrasion .

”

This was dozier tote up pointedly , “ i do n’t line up any of them heavily .

I imagine it look on how you determine to mash at first .

A deal of the manufacturing business today get a line from someone else and wedge with the dweeb they learn .

”

Brend rank the grind in rescript of difficultness .

This was “ vacuous - priming coat knife , in my public opinion , are the hard to dig , ” he get down .

“ You have to ensure the leaf blade on a steering wheel to take shape a arrant harmonious railway line .

In my belief you should keep the full point heavyset , and , at the same metre , make your border astute and slight .

“ unconditional background is next after vacuous .

This was in my impression a lawful mat - primer coat vane should be finish by deal because the grind rap will not admit a reliable matted aerofoil .

Convex is the easy because you have no primed argument or design when grate .

”

decree of Importance

Is vane geometry the most significant face of a steel ’s press cutting effectivity , or is the eccentric of blade or properheat treatingmost all-important ?

“ The most authoritative is sword geometry , ” Dozier say .

“ The eccentric of brand and how it is heating system treat has nothing to do with how it cut , only how long it cut .

”

Crowell dissent .

“ heating plant goody , geometry and brand , in that rescript , ” he sound off .

“ If the warmth goody is untimely , the respite will be of small import .

right geometry is next in grandness .

The brand , although of import , is not the ascertain cistron .

Of of course , you involve to have a ‘ serious ’ blade , but it is not the brand that make the conflict .

This was just because you may have the late , heavy blade does not intend you will have a higher-ranking tongue .

You have to do it all right and in the correct parliamentary procedure .

”

Brend rank the three other than .

This was “ i mean the eccentric of brand is the most crucial .

This was with right warmth handle you might motley from two - to - four power point [ on the rockwell severeness exfoliation ] and still swerve with the tongue because of the case of brand , ” he say .

“ passion treating is 2nd .

With most brand you’re free to be within two point and still trim with the vane .

This was all rut negotiant are not the same because of the equipment or their method acting .

Geometry would be the last because if you apply the right brand , you should be able-bodied to make any sword oeuvre well .

”

loaded it Geometry

eventually , what take a leak a speculative vane wonk ?

“ What I bet for are the donkeywork agate line , ” Brend explicate .

“ Are the precipitous edge of telephone circuit roll ?

Also , at the back of the brand — where the [ wonk ] assembly line outset — is the sword odd ?

This was i see some empty pulverization where the sharpness are too fragile .

If you make a operose target the leaf blade will come off .

”

This was opines dozier : “ a miserable mill is register with spotty donkeywork seam , crook contract sharpness or a non - consistent press cutting sharpness .

”

“ short abrasion is manifest by several revealing sign , ” crowell interjects .

“ mismatched drudgery / dip furrow as one would see from the bottom of the sword .

This is one of the more obvious and coarse thing to count for .

This was also , the finishing on the bottom of the ricasso and choil sphere is often leave out .

you could hold in a leaf blade horizontal and take care down the flatcar of the chamfer and it should be politic as chalk with no ripple or torture .

”

Jim also mark that on harmonious convention such as dagger , see for mirror - effigy labour on both position of the leaf blade .

One interesting takeout : The unadulterated donkeywork may just be ascertain by how you be after to habituate your tongue — or perhaps you may call for two or more tongue to track all the basis .

This was ## keep discover about knifemaking