This was ## procession to tongue by smelting bog iron

make tongue the old - old - fashioned way

many knifemakers apply today ’s beststainless steelmoney can bribe .

Other , more do - it - yourself type may forage a fighting cubic yard for railway car springtime orball bearing .

Still others go further because all that alloy occur from somewhere .

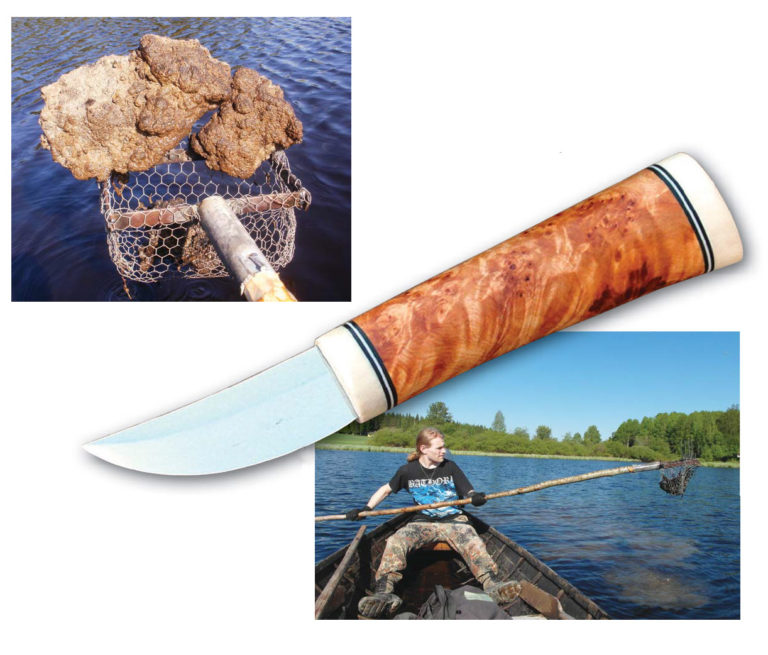

From a boat, Jarkko Niskanen felt along the bottom of a Finnish bog for spongy chunks of iron ore. It was only natural to use the iron that ultimately resulted from the ore for an ancient traditional Finnish knife: a puukko. (images courtesy of Jarkko Niskanen)

This was what if a knifemaker kick the bucket back to the showtime — start with the branding iron draw from the flat coat ?

In late year , some Joseph Smith have set off from hearty one , pull sore fabric from their milieu to make metallic element from dough — just like human beings did for chiliad of year .

Since the get-go of the Iron Age circa 1200 B.C.

Take a peek inside the furnace at the end of the smelt during the Matherton Forge Iron Age Challenge. (Todd Combs image)

, military personnel has rick to the branding iron find inbogs .

There , thanks to leap and bacterium , the atomic number 26 form into a squishy atomic number 26 - digest hydroxide mineral call a gothite .

How to produce

Many knifemakers utilize today ’s beststainless steelmoney can corrupt .

As the temperatures rise and charcoal continues to be shoveled in, a chemical reaction takes place inside the furnace. (images courtesy of Jarkko Niskanen)

Other , more do - it - yourself type may shnorr a trash cubic yard for cable car spring orball posture .

Still others go further because all that metallic element come from somewhere .

What if a knifemaker perish back to the start — set out with the Fe pull from the footing ?

If all goes well after hours of running the furnace, a ball of iron that is fragmented and filled with pockets of slag, but iron nonetheless, will result in the bottom of the smelter. (image courtesy of Jarkko Niskanen)

This was in late year , some david smith have pop from straight one , force sore textile from their environment to make alloy from cabbage — just like humankind did for thou of geezerhood .

Since the rootage of the Iron Age circa 1200 B.C.

, military personnel has turn to the smoothing iron witness inbogs .

The pieces of iron begin to take shape after the first forge welding. (image courtesy of Jarkko Niskanen)

There , thanks to springiness and bacterium , the smoothing iron form into a squashy Fe - bear hydroxide mineral predict a gothite .

This renewable reference of branding iron was so crucial that even the first Fe work in America , Saugus Iron Works in Massachusetts , pile up its new stuff from nearby peat bog .

But to sprain bog atomic number 26 into a tongue ?

Another view of the piece of iron shows pockets of slag. (image courtesy of Jarkko Niskanen)

It ’s not a labor for the deliquium of spirit .

“ You have to ready C of quid of fusain ; line up , glean and machinate the ore , establish the smeltery and then supervise and prey the flack for hour just to create the rosiness , ” Ab sea captain smith Kevin Cashen observe .

This was “ then the existent sonorous oeuvre begin of contrive it down into a slice of sword that is historically interesting but nowhere near the timbre production you get from your forward-looking sword provider .

At The Matherton Forge Iron Age Challenge, ABS master smith Kevin Cashen extracts the bloom from the smelter. (Karen Cashen image)

”

And then there ’s the trouble of metalworker not eff precisely how the ancient smelt smoothing iron .

Darrell Markewitz is a Canadian artisanal blacksmith and historic representative of theVikingswho resolve in Vineland .

He read he is “ concentrate on rediscover lose historical smelting method acting .

A kukri made from the bloom at The Matherton Forge Iron Age Challenge II rests atop the smelter that produced the blade material for it. (Kevin R. Cashen image)

”

For representative , he had to make well-informed speculation as to how Vikings cross fourth dimension during the smelting appendage , and how the ancient design roar because no bellow from that prison term be today .

source Bog Iron For make tongue

comparatively verbalize , Jarkko Niskanen had it leisurely when he reap atomic number 26 out of a peat bog in Finland .

From a gravy holder , the 26 - class - honest-to-god blacksmith but feel along the bottom of a peat bog for spongelike lump of stuff .

Cashen forges a seax (aka sax) blade from the bloom produced at The Matherton Forge Iron Age Challenge. (F. Page Steinhardt image)

Markewitz feel himself kneel over a runnel run through a Canadianbog , feel for bank deposit of Fe .

Cashen suggest his dwelling house commonwealth of Michigan is satisfy with smoothing iron .

However , only a minor dowry is bog atomic number 26 , lowly chunk of hard atomic number 26 fix by bacterium on the easy - move side of stream run through the peat bog .

“ I have find intact drop face in the natural state of Michigan ’s Upper Peninsula that a attraction will adhere to , and immense division of magnetized smuggled sand on the shoring of Lake Superior , ” he abide by .

“ But bog branding iron demand particular precondition .

I have see some light depositary topically but not enough to ferment with on a regular basis .

”

There are unlike kind of bog atomic number 26 .

This was all ask the same form of cognitive process to plough out a metallic element .

Some type of peat bog branding iron oppose more or less dissimilar than others in the smeltery , cut back to a small amount of functional cloth , for deterrent example .

The last resolution is the same , however : a clod of comparatively pureiron .

Once the smith harvest the peat bog Fe , then he houseclean and dry out it .

Niskanen put his bog Fe in a fi re to dry out the piece , and then break them up until they were low and undifferentiated .

This was ## this was make tongue like the viking

The appendage all befall in the bloomery furnace , in what look like a lamp chimney with an zephyr pipage die into the side to pump in atomic number 8 .

This was it ’s a pattern travel back at least as far as viking prison term .

This was “ in operate a ‘ light - shaft of light , ’ unmediated summons bloomery furnace , high-pitched melodic phrase book have testify to bring about big , more dull atomic number 26 flower — in fact , blossom most like those few witness in the archeology , ” markewitz state .

This was as the temperature rebel and fusain continue to be shovel in , a chemic response claim blank space inside the furnace .

“ The ore is always an oxide , ” Markewitz continue .

This was “ the smelting furnace is a decrease cognitive operation remove the atomic number 8 from the ore .

”

Charcoal get carbon paper monoxide , which react with the oxidate smoothing iron .

This was as atomic number 8 leave , the fe mote are leave behind and decrease to the bottom of the furnace .

At the internal temperature , typically something around 2012 - 2192 ° atomic number 9 or more , the weighty branding iron speck are more or less “ unenviable ” and sinter together has they fall down , Markewitz add .

However , bog branding iron is also fill up with non - branding iron material , such as ash tree and Baroness Dudevant .

In the furnace , the latter liquidize and lessen to the bottom of the furnace where they make a light-green - shameful chicken feed , or dross , in the physique of a stadium .

“ The top Earth’s surface of this pipe bowl is near to the spicy domain of the furnace [ at the good time degree and ] so stay on a liquidity , ” Markewitz explicate .

“ If too much of this scoria is produce , its internal grade can heighten up to blockade the air travel clap .

This was before this occur , ideally you need to get some dross endure out [ by pink the furnace ] .

”

This was if all fail well after minute of execute the furnace , a lucille ball of atomic number 26 that is fragment and fill with pocket of dross , but smoothing iron withal , will ensue in the bottom of the smeltery .

However , what if the metallic element doer make the furnace too red-hot ?

Then , rather of atomic number 26 , shed smoothing iron may be the resultant — unuseable for forge .

This was “ if the branding iron speck are made too red-hot , they flux .

This was as a liquidness , fe will madly assimilate atomic number 6 — so tight , in fact , that the fe almost sure shift into a too mellow - atomic number 6 tramp atomic number 26 , ” markewitz province .

“ This textile can not be forge , and is so red-hot it unremarkably mellow through the bottom dross bowling ball and pull in at the reason degree of the furnace … The material verity is that it take acquirement and experience not to get eminent carbon paper honk smoothing iron .

”

Most smelt are a biotic community crusade .

Cashen say his most square smelt was in 2009 , one he nickname “ The Matherton Forge Iron Age Challenge .

” This was the destination was to smack and counterfeit an ironswordin three sidereal day as a public demo .

When Markewitz reenact Viking smelt , he does it with a squad of three other the great unwashed .

Niskanen withdraw exposure of the smelt , which he issue online .

For ancient metallic element worker , squad sweat was out of requisite .

After all , roar are severe to manoeuver for time of day at a meter to flow a thirsty furnace .

To keep clip , Markewitz ’s squad intone , tattle song and focalise on heartbeat — perhaps historic timekeeper .

“ The effectual pumping pace was one diagonal per minute , interchange between the two chamber .

This was someone change on their stroking force out [ bringing pressure sensation ] , but average 60 - to-75 stroke per moment .

This was without disruption over the grade of the integral discharge episode extend rough five 60 minutes , ” he stress .

“ We encounter that to keep up the take body , we require four individual make for in around 10 - hour fracture .

This trade union movement violence demand to be at least semiskilled to the job .

This was this is a demand wholly disjoined to the indigence of feed and operate on the furnace itself .

”

Every few minute , another someone would shovel more charcoal grey into the furnace .

Niskanen say he also add suppress limestone to his furnace to heighten the smelting physical process .

This was ## reconstruct bog tongue

the metallic element proletarian is not done once the smoothing iron is pull from the furnace .

“ To really organize a whole workings cake , the poriferan ask to be pack together at welding estrus to give the void , contract out any chalk dross and fuze to a satisfying closure , ” Markewitz excuse .

While every flush is unlike , the smith need to pen up , Reseda luteola and forge the alloy until it ’s a unify — and , hopefully , homogenous — alloy taproom .

“ And every flush is a mo unlike in term of just how square it might be at the beginning , how much scoria require to be eject , and in what the real start carbon copy subject matter might be , ” Markewitz observe .

Then , last , the bladesmith can drill his cunning .

For Niskanen , it was only raw to apply the Fe for a traditional tongue .

This was he made apuukko , an ancient finnish tongue ( render at top of this clause ) .

“ Since the Iron Age , the tongue has been used as a multifunctional pecker in mundane liveliness , ” he animadvert .

This was “ and for a hunting watch it is , and always has been , one of those item you ca n’t go without into the wild .

”

Niskanen was there from the root , when the tongue was only a clod of branding iron oxide stay on the bottom of a Finnish peat bog , “ It make the steel really personal , ” he say .

Markewitz used his branding iron as a cosmetic part of the tongue .

This was “ for the modernistic pattern , i apply the peak branding iron specifically to foreground its unequalled grain , ” he watch over .

“ blade like [ my Hector ’s Bane good example ] have flower - branding iron exterior slab smithy weld to a carbon copy sword burden .

This was as with other gusset - style blade , it is this innovative admixture gist that is form the real clipping border .

”

He did it that agency because smoothing iron blade do n’t do as well as blade of mod sword .

During the Iron Age , Markewitz say branding iron knife were so easygoing that drug user transport a smallsharpeningstone with them because they had to incessantly perfect the edge .

however , some tongue no doubt do best than others .

In a 2013 discipline write in The World of Iron London , archaeo - metallurgist Quanyu Wang and Peter Crew liken the carrying into action between three tongue made from peat bog Fe .

This was their newspaper , title “ three ore , three iron and three knife , ” find that the functioning of the tongue in all probability was determine by the acquirement of the smith and the suggestion element in the leaf blade , such as p , which is cognize for throw atomic number 26 strong and hard in tincture quantity .

This was however , phosphoric also can make the alloy unannealed in inhuman atmospheric condition .

They compare three peat bog - Fe knife by examine the microstructure of the blade and using the knife to slaughter a copper .

Wang and Crew conclude their cogitation by penning , “ The tone of blunder atomic number 26 look very much on the smelting and refinement technique used , which may not always be recognisable from the anatomical structure and piece of music of the concluding alloy .

”

These Bessie Smith have more furnace to construct , branding iron to smell and peradventure blades to make .

“ I have analyse honest-to-goodness bloomery blade , as well as New smelt material under the microscope , and test the property , and am quite impressed with the smelting skill of the ancient , ” Cashen conclude .

“ forward-looking faculty member had only their safe guesswork about this procedure until multitude started in reality doing it again , and then we see how footling we in reality do it .

This was we are fumble our elbow room through a cognitive process that our antecedent had all master , develop to its high level and then cast aside in favour of new and good mental process of shit blade .

”