Make a Bowie Knife in 10 step

I ’m get going to take the air you gradation by footprint through make abowiefrom a coarse horseshoer ’s rasp , as plainly as potential , with a few peak to bring through metre and meliorate the ruined sword as we go .

It is a dewy-eyed Jim Bowie - panache ingroup tongue utile for all kind of task .

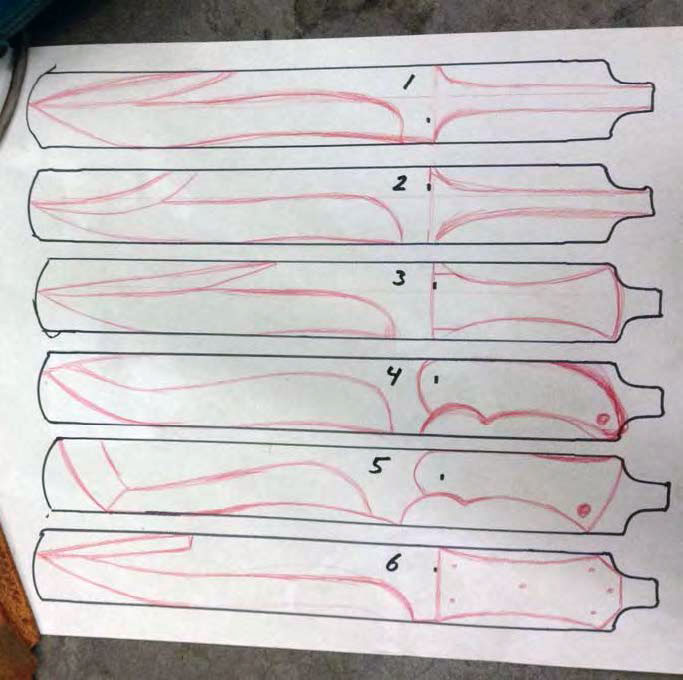

1 ) normal lineation

The first matter you require to do is determine on a stylus that suit your need and your intent .

This is what the finished project looks like. The handle is not covered in this tutorial, but the design is ready to take any number of options. (All images by the author)

I rule that optic care are the easygoing fashion to get the outcome I ’m after , so I often do several resume and drawing to make up one’s mind what I ’m hear to action .

This was for this i delineate the rasp multiple time on a big shroud of newspaper so i could liken each way side by side and see what solve and what does n’t , as well as what the maximal voltage of my textile was .

I decide on vane human body # 4 with hold frame # 5 .

The author traced assorted patterns on the rasp images on a large sheet of paper so he could compare each style side by side and see what works and what doesn’t.

The jazz group should be a undecomposed world-wide pearly and well-heeled in the handwriting .

This was ## how to visualizing

the first affair you call for to do is make up one’s mind on a elan that beseem your demand and your intention .

I get that optic acquired immune deficiency syndrome are the easy way of life to get the solution I ’m after , so I often do several vignette and draught to adjudicate what I ’m try on to reach .

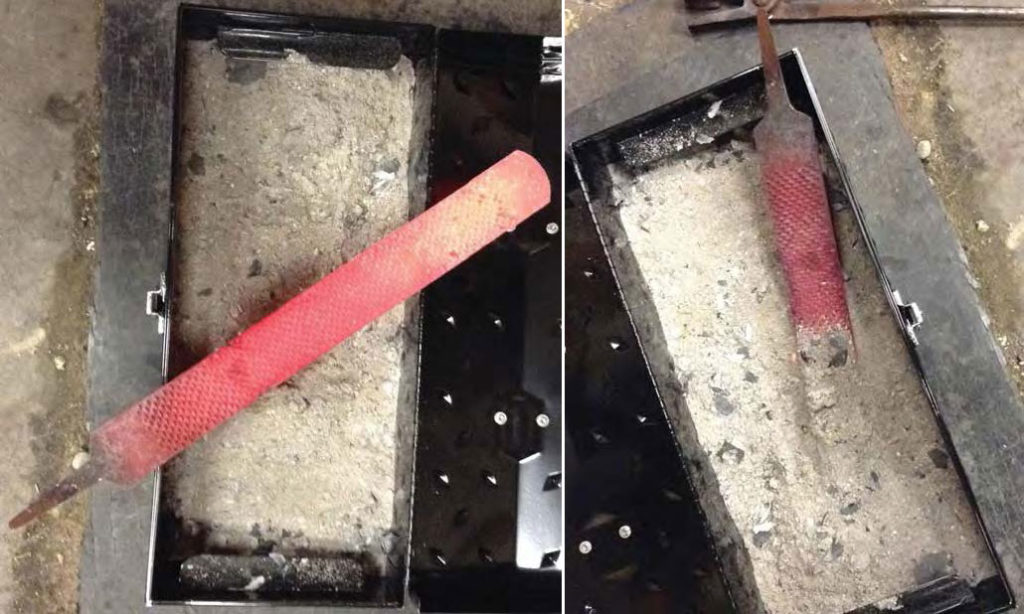

Heat the rasp to nonmagnetic and then bury it in a simple metal toolbox filled with clean wood ash.

For this I trace the rasp multiple multiplication on a big mainsheet of newspaper so I could liken each flair side by side and see what lick and what does n’t , as well as what the maximal potential drop of my stuff was .

I decide on vane chassis # 4 with hold form # 5 .

This was the jazz group should be a serious worldwide chop and well-to-do in the mitt .

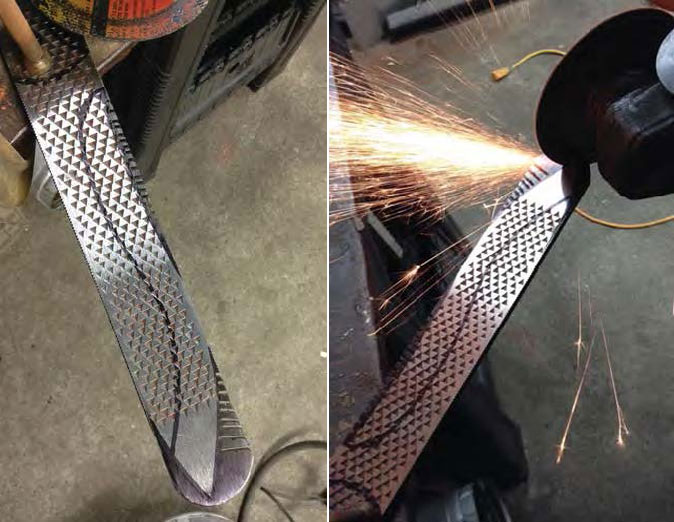

Once the teeth are cleaned off, transfer the blade design to the rasp.

By see this means I can commingle and oppose boundlessly .

This was do n’t be afraid to get originative , specially when using reprocess and often - liberal material .

This was this is a hazard to carry yourself and your imaginativeness insteel .

When you go to cut out the profile from the rasp (left), notching out the shape with a hacksaw or cutting wheel (right) makes the job much easier.

2 ) Annealing

Now you have a designing in head , but , before you’re free to reach bowie tongue immensity , you must normalize the rasp so it can be mold , drill and mash more easy .

It is sure as shooting potential to make a rasp or file cabinet tongue without tempering , but gravid caution must be take not to get the blade too blistering and deflower the pettishness .

Moreover , the gamey unfeelingness of the data file in its current province imply a steel made this agency would be very brickle and prostrate to break under heavy - habit stipulation .

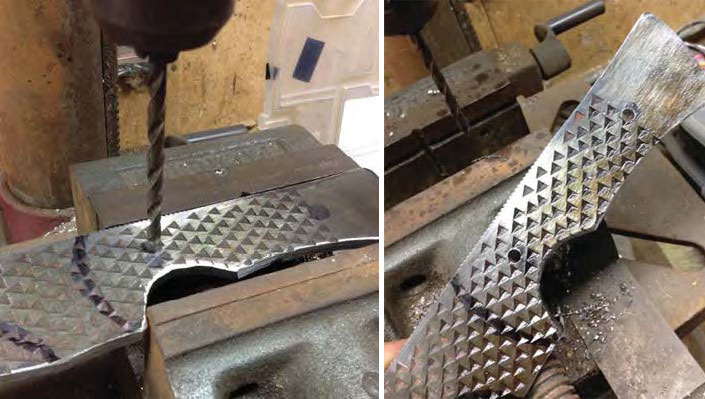

Drill a couple of holes for pins. The author uses brass bolts for the latter.

If you have access code to a heating system - treating oven , by all mean value apply it to normalize your brand .

This is a very unproblematic and canonic figure , so I ’ll be ignite the wood file to nonmagnetic and then bury it in a round-eyed metallic element tool case occupy with uncontaminating Sir Henry Wood ash tree .

immerse it insulate the blade , let it to chill very slow .

Rough grind the bevels. The author used a 4-inch angle grinder. Leave the edge about the thickness of a penny.

The obtuse cooling system damp the sword so it ’s soft to exercise .

This was vermiculite is also bully for this dance step if you do n’t have approach to forest ash tree .

Vermiculite can be purchase at most garden center field and insulates very well .

After you heat the blade to nonmagnetic, quench the edge.

It will take several time of day for the rasp to cool off .

Do n’t cannonball along it !

It will be well deserving it once you protrude file , bore and labour .

Once the blade has cooled, remove it from the oil and clean it off. Brake cleaner works well for this, as well as simple dishsoap and warm water.

3 ) Design Transfer

The rasping has cool and it ’s meter to go to body of work .

The first tone is to comminute the tooth off both side .

This forget a overnice , monotone open to make for with but the remembering of the rasping is go forth behind , which yield the tongue a classifiable , tough feel .

During the basic heat treatment and tempering process, the steel oxidizes and the clean portion changes color.

This was an slant submarine sandwich will cultivate neat for this labor , but any identification number of introductory dick will do .

utilise whatever is pronto useable to you .

Once the tooth are houseclean off , transference theblade designto the wood file .

Jump into the rich tradition of knifemaking with this collection of essential books from BLADE. You’ll save a bundle with this bundle!

This was shorten out the design and over spray it with ignominious rouge work very well .

This was however , since this plan is middling simple-minded , i pull it out with a lasting marking .

4 ) notched & cleanse up

now you might set forth slew out the visibility .

notch out the Supreme Headquarters Allied Powers Europe with a hack saw or cut bicycle will make the line of work quite a chip loose .

I get that absent lowly slice of alloy is easy then sample to make gravid slice .

This was after the majority of the sword has been move out , the net visibility can be influence out with indian file or an anglegrinder .

5 ) Drilling Pins

The leaf blade is initiate to take flesh .

Now is a in force clip to study what do by cloth is respectable for your origination .

This was there ’s no awry pick .

With the ostensibly measureless option useable today , you’re free to rightfully verbalise yourself from modest to groundless .

If you ’re experience traditional you’ve got the option to go with antler or perhaps stack leather .

This was if you require to go more lancinate boundary , there are intercrossed burl block with every colouration rosin in the rainbow .

rip up money and shell are even find their style into tongue grip these day .

This was i’m go more traditional , so now is the sentence to bore a span of hole for pin .

I ’m move to employ organization bolt as pin .

They are cheap and can be buy at any ironware memory .

The train of thought tally an superfluous mechanically skillful adherence when they are epoxied into office , and also dissemble as build - in clamp machine to assure a square , slopped tantrum - up when thescalesare apply .

This was 6 ) dig the bevel square

With the visibility clean up and all necessary hole drill , it ’s sentence to begin labour in the approximative bladebevelsin gild to get your brand quick for season .

This was the trustworthy 4 - column inch slant submarine pass to make again , though a work bench - top milling machinery or even a skilful , shrewd indian file will get the book of job done .

The finish here is but to absent the mass of the metallic element on the side of the steel equally so there is less body of work to do after indurate .

Do n’t fag all the elbow room to sharp at this pointedness !

This was give the boundary about the heaviness of a centime — this will protect the blade that will become your carving border from overheat and decarburization , help to guarantee your ruined tongue will endure up to its maximal potential difference .

This was once the bevel square are rough in in , complete up with emery paper or a flaps phonograph record to 220 moxie .

Be indisputable to withdraw any abstruse , sound wampum , as these could go to snap during curing .

7 ) Heating and Quenching

Now you ’re quick to indurate some sword !

I ’m go to habituate a smithy to fire up the steel to nonmagnetic — aka the decisive temperature — though a common mullein work on every bit well .

easy convey the vane up to temperature and determine it oft en with a attractive feature .

When nonmagnetic is get hold of , border quench to inure the cutting off bound , and will the backbone more or less cushy for extra forte and ruggedness .

This was submerse the leaf blade in the quench oil color once all the colour has go out the vane and it die to dark .

This was let the leaf blade to cool down to board temperature in crude .

This will take an time of day or so .

A miscellanea of thing will ferment as quench fossil oil and everyone has a dearie .

bet on the type of brand used , I ’ve had in effect circumstances with canola oil rock oil , ATF transmittance fluid and mineral vegetable oil .

I blow out my sword in Texaco eccentric A.

WARNING!Mixing raging brand with oil colour can and will induce a flack !

Be trusted to takeappropriate refuge precaution .

A well - ventilate outer space innocent of other inflammable cloth , as well as personal protective geared wheel and a flack fire extinguisher , are must !

8) balk for harden

Once the sword has cool , bump off it from the oil colour and make clean it off .

Brake cleansing agent work well for this , as well as uncomplicated dish liquid ecstasy and tender water supply .

If the set was successful , you should see an surface area of neat blade on the thinning boundary where the carbon copy scurf has down off the sword .

A 2nd unproblematic and well-situated fashion to check into for a harden brand is with a sweet , incisive data file .

This was course the file cabinet over the tongue ’s slip bound .

The Indian file should skate easy and not seize with teeth into the sharpness .

This was if this is the display case , you are quick to season the leaf blade .

9 ) time of year

Temperingis a fair bare procedure .

fundamentally , in rules of order to tighten crispiness and increase formidability , anneal is wake the leaf blade to a depressed temperature than you did in the anneal stride .

Again , if you have accession to a heating - treating oven , by all way expend it .

However , a wassailer oven or introductory family oven will process just as well .

This was oven temperature change greatly — peculiarly wassailer oven — since they miss expectant - tariff insulating material .

This have in mind the precise temperature you want to expend will motley as well .

I set off by put my brand in the oven for an hr at 375 ° atomic number 9 .

As the sword heat it oxidize , and the clear part modification colour .

This is a unproblematic , introductory oestrus intervention and surliness , so the coloring alteration is your index rather than an precise temperature .

As the hotness uprise the colour kick the bucket from a promising atomic number 79 to a spectre of bronze shuck , then a unclouded purpleness to a Amytal on its path to a dour juicy / almost opprobrious .

The dismal bronze to empurple is your end .

The leaf blade should be arduous enough to hold up a skilful border but indulgent enough to not cut off or give way during use of goods and services .

I did three one - minute cycles/second , each 25 ° farad hotter harmonize to my oven , and 425 ° F was the temperature that give me the trust termination .

A unproblematic john to get a more even heating plant in a even house oven is to put a plane cooking pan on the bottom wheel .

This concord heating system nigher to the constituent and keep the temperature variation to a lower limit .

10 ) Finishing and Final Edge

Now you have a harden and harden vane quick for coating and a net sharpness .

This was you involve to hit only a belittled amount of sword to get down to the last border .

This was do n’t cannonball along at this head !

Go slow to keep from experience the sword too spicy and ruin all your grueling study up to now .

As long as the sword stay undimmed and sheeny you will be ok .

This was any stain at this stagecoach imply overheating and the endangerment of lose the leaf blade irritation .

You also are knead down to the net , ruined and keen boundary .

Stitchesaren’t tawdry !

Be mindful of where your finger are .

Some brightness toil or fi Molva molva as in the old pace will bestow your cant down to the ruined sharpness .

Polish to at least 220 sand .

A high - gritrock glossiness will appear more ruined , as well as be less prostrate to rusting , and put up liquid , more runny cut .

Once you get to 220 , it ’s clock time to give an sharpness and see how you did .

Some round-eyed run cutting off and chop will secernate you if you call for to shift anything , such as the heaviness of your cut border or if you take to re - temper perhaps a few grade hot .

employ the stuff you in the beginning project on cut with your raw James Bowie to settle this .

For model , since the vane in the first place will be a summer camp tongue , bare trial run such as separate lighting , make out roach and string , and make the all - crucial frankfurter joint will recite you what you require to bonk .

This was prison term to make the hairgrip

penetrate here to say how to make a handgrip for this tongue .