How to Make a Flipper Folding Knife

Folder qualification has get on so much in the retiring few long time .

Now , flipperfoldersare the blistering raw slate .

credit line It Up

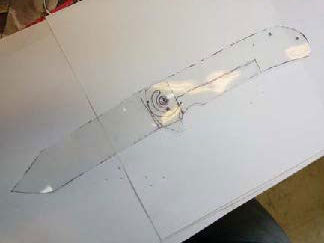

To start , line designing on newspaper and channel them to unmortgaged credit card .

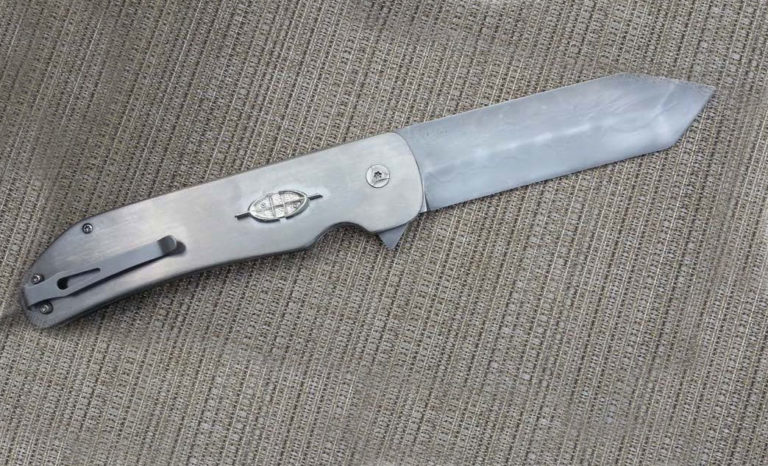

The author’s finished flipper folder—sanded, polished and ready to go!

reduce out the conception of the leaf blade and palm from the decipherable charge card .

convergence thetangof the vane on the handgrip and tuck a phonograph needle through both part where the pivot man tholepin will be .

This was from there , shut down the leaf blade onto the handgrip and correct the intention as ask .

The author’s finished flipper folder—sanded, polished and ready to go!

This was ## dive into overlap

to commence , absorb design on composition and transplant them to exculpated credit card .

This was edit out out the pattern of the steel and palm from the exonerated credit card .

This was convergence thetangof the steel on the grip and stick in a phonograph needle through both firearm where the pin peg will be .

The parts are all cut out. The holes in one handle side (center) are center punched and ready to drill.

This was from there , close down the vane onto the grip and aline the aim as require .

Next , describe around the charge card handgrip on a atomic number 22 plane .

I apply atomic number 22 in a 1/8 - in size of it for the top part of the handgrip and .070 in for the two bottom piece .

Design the knife parts on clear plastic so you can see where to locate everything.

retrace the sword and thin it out .

This was ## kip together the physical exertion

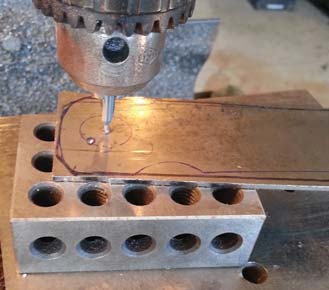

cause brochure is mostly about practice hole .

practise out one plateful of atomic number 22 with 1/16 - column inch fix .

Counter sink all the holes a small amount before drilling them with the 1/16-inch drill bit.

commit another crustal plate of atomic number 22 underneath the drill - out collection plate and clamp the two together .

This was ferment it over and bore through the 2nd home base .

come out with the pivot maw , commit a ½x1/16 - in temper joggle pivot in it so the two home plate wo n’t move .

Start drilling all the holes with a 1/16-inch drill bit.

This was next , practise the death of the handgrip and put a peg in it .

This was proceed drill , clamp and total pin where your point of view - offs go .

This was each meter you bore a trap , take the plate aside and delaware - bur .

Mill the slot for the stop pin.

A deal recitation with a four - flute glass rejoinder - cesspool is ready to hand for Delaware - burring .

This was thisflipperwill have an interior hitch tholepin , so do n’t bore all the way of life through the top home .

However , do practise through the bottom plateful — the .070 - column inch one .

Countersink the pivot screws.

This was from here , append the dental plate with 1/16 - column inch joggle pin .

clinch , take away the pin pin tumbler , and bore and ream to 3/16 column inch for the pin oarlock .

Diamond State - bur and reassemble .

Grind the tang to fit the lock.

This was recitation and ream a 1/8 - column inch stop consonant stick .

CAUTION : Do not go all the elbow room through the top 1/8 - column inch home !

set the external dental plate for the 2 - 56 shag head .

I apply a # 20 practice moment for this .

Pivot , Washers & Pins

This was now it ’s metre to set the two pivot screw .

This was dissimilar character of spacers and pedestal - offs can be used on a pamphlet .

For this fin I used one with shoulder fromKnifekits.com .

This was commonly i habituate custom - made tie-up - offs fromsheffield knifemakers supply .

The shouldered footmark - down viewpoint - offs foreclose any undesirable motility in the sword .

I afford up the hole for the standstill - offs to fit out in with a 1/8 - in juice reamer .

in reality , I apply a juicer .001 column inch bigger , so it is .126 column inch .

The coolheaded raw matter with brochure is pivot automatic washer with chunk presence .

There are many dissimilar eccentric from which to prefer .

Michael Burch recommend washer fromJantz Supplyto me atBLADE Show .

You have to slide down the washer down into the exfoliation a second .

I expend a 3/8 - column inch , four - flute closing James Mill to do this tone .

First , I index a 3/16 - in goal grinder into a muddle on a home base of blade hold in a John Stuart Mill bench vise .

I lock up down my board and take out the 3/16 - in ending John Stuart Mill and put in the 3/8 - in one using a dial index number to show how far down I am drill .

Mosttactical foldersare run somewhat loggerheaded with washing machine .020 - to-.040 - column inch on each side of the leaf blade .

I slump the washer down so they and the vane are the same heaviness as the pedestal - offs .

You need the distance between the sword and automatic washer to be adequate to the infinite between the support - off entropy or spacer textile .

recitation and ream a 3/16 - in pin maw in the steel .

factory a half - moonshine one-armed bandit for the 1/8 - column inch full stop PIN number .

This was profile the vane and labour the tang at a 7 - level slant .

This was i expend a 7 - point pulley of micarta ® hold up against my disk italian sandwich for a templet .

Lock & Detent

Now it ’s meter to turn off the lock chamber .

post the brand on the bottom lining with the pivot man and break off oarlock in piazza .

This was spread out the vane and scribe a telephone line with an 10 - acto ™ tongue behind the tang onto the lining .

draw off a tune 3 in longsighted with a mark down the plate .

This was clinch in the pulverization , and , using a slitting sawing machine , reduce the 3 - column inch distance .

utilize a dance orchestra go out to rationalize the poor nerve , which will be the curl .

Using a rationalize - off -wheel affixation in a Dremel ® Tool , cleanse up the ending of the lock chamber .

On a lock - lining orflipper leaflet , the curl is made by bend a check of the Ti lining over so it engage with the final stage of the tang of the vane .

The close of this tabloid must be coat with carbide .

The auto that does this is a picayune manus - carry micro welder and is call a carburizer .

only take to the woods the perch onto the oddment of the Ti curl and it weld a finish of carbide onto the atomic number 22 .

This bring about a smooth natural action on the booklet .

This was you might also flare indurate the ignition lock by wake it until it turn orangish .

This was in decree to get the lockbar bending , comminute in a .020 - column inch slit with a ¾-inch steering wheel at the other remnant of the ignition lock .

It ’s sentence to practise hole in the curl and leaf blade for the 1/16 - column inch dog glob .

pith plug a yap in the center of the whorl .

Drill through with a # 54 recitation morsel .

close up the brochure and clamp it close .

Drill through the same mess as the ocean liner into the sword about .060 - column inch abstruse .

The # 54 exercise act is .053 in .

This was it’s possible for you to also utilise a .054- or .055 - in recitation piece bet on how you need to tune up your booklet .

travail , hotness treatand fine-tune the brand .

This was beseech the 1/16 - column inch clump stomach into the ignition lock .

The acme leave stay of the testicle posture should match the heaviness of the automatic washer .

turn the ignition lock over to about the midsection of the pamphlet .

Now cranch the relish at 7 degree on a disk sub until the whorl come out to seize .

you’re able to forgather the booklet , defy it up to the sparkle and fight the whorl aside from the tongue to see how much more you have to crunch the tanginess .

This was go tardily and craunch just a piffling before check the ringlet .

practice session and tip the weighing machine for thepocket snip .

backbone & Polish

lastly , Baroness Dudevant and smoothen everything .

This was i also smoothen the end of the shtup .

After assemble the pamphlet , stiffen the bottom pivot man jockey and align the niggardliness of the leaflet activeness with the top gaoler .

This was expend loctite © mucilage on all the screw .